Next-gen Nanocoatings Offering Unparalleled Electronics Protection: our investment in actnano

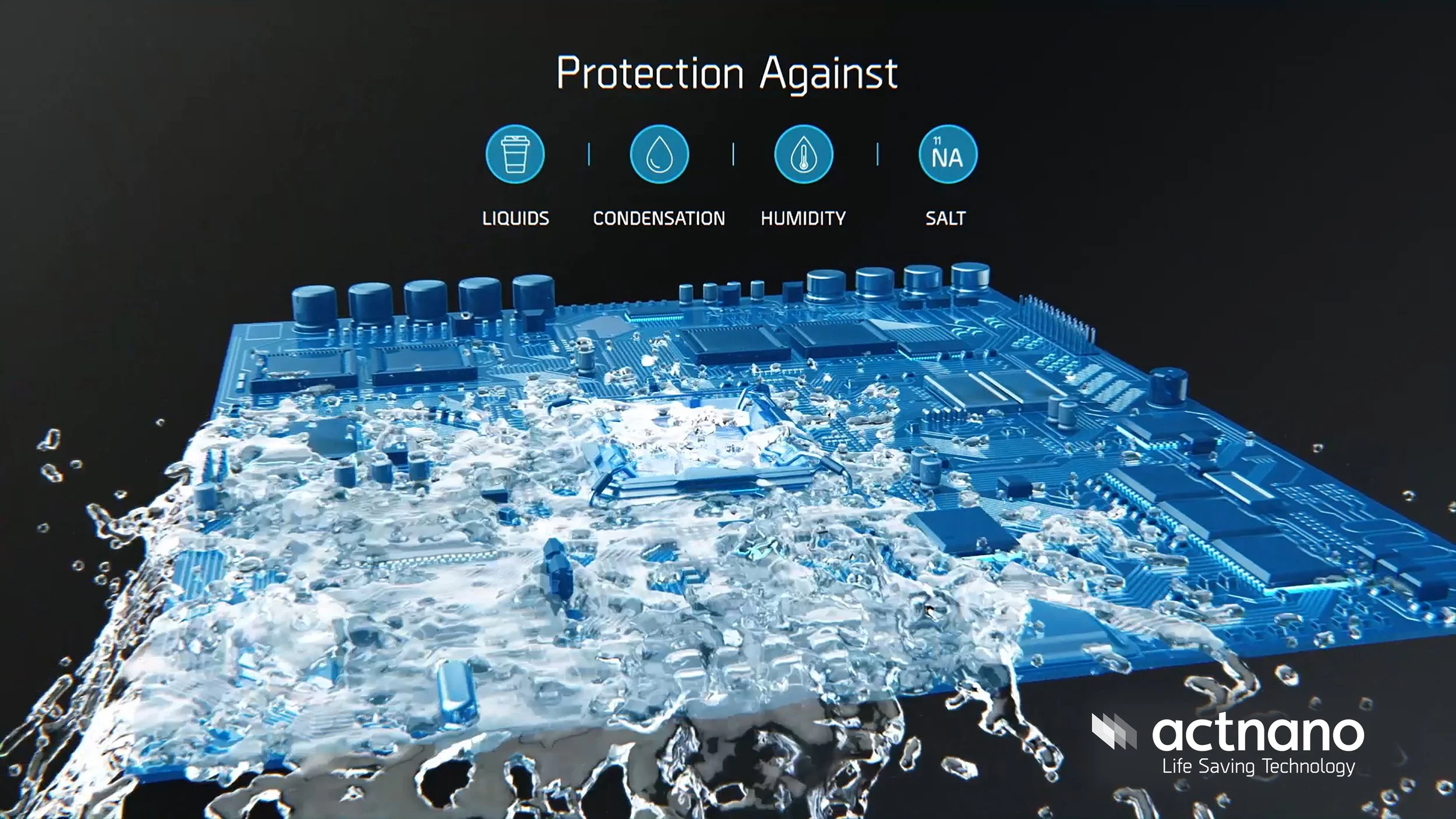

Image: actnano’s nanocoating solution provides comprehensive protection of electronic components from the elements.

We are thrilled to announce our lead investment in the Series B financing round of actnano. Actnano has developed a gel-based, hydrophobic nanocoating that enables protection of electronics from environmental degradation with greater reliability and at a cheaper cost than both conventional and emerging coating alternatives. With its coating technology, actnano has set a new standard for electronics protection in consumer and industrial markets, enabling the application of coatings across electronic components previously left unprotected by existing coating technologies.

Coatings act as a protective barrier to prevent electronic components from breaking due to environmental factors like condensation, humidity, and salt. For example, with the right protective coating, you can effectively “dip” your smartwatch or earbuds into water without frying the electronics. In recent years, as devices have become increasingly more sophisticated and are being used in more safety-critical environments, manufacturers have begun seeking better protection of their devices through broader application of coatings. The proliferation of electronic components in the car, particularly with the advent of autonomous driving and ADAS and the move towards vehicle electrification, necessitates greater protection of such components because of their use in situations where the lives of drivers depend on their continued operation.

While coatings exist in many electronics today, coatings in the market today fall short of achieving full protection of the electronic device. The incumbent technologies (i.e. conformal coatings; mechanical seals; and vapor deposition) suffer from poor performance and reliability or are prohibitively expensive to use in production. While the emerging category of nanocoatings offer superior performance and reliability over incumbent technologies, they too are very expensive and time-consuming to use in manufacturing in comparison with actnano’s technology.

By contrast, actnano addresses the limitations of current electronic coatings by producing a gel-based, hydrophobic nanocoating that enables protection of electronics from environmental wear and tear while reducing the costs of applying the coating. They are addressing the main pain points of the electronics coating industry in the following ways:

Superior Performance and Reliability: actnano’s coating product provides protection against humidity, sweat and salt, operates without overheating electronic components, does not crack and maintains signal integrity .

Expanded Use Cases: As vehicles use more electronic components, automotive players are seeking coatings for increasingly more use cases to preclude electronic malfunctions in cars to maintain a strong standard of safety. With its solution, actnano enables new use cases across components that may not have used coatings in the past.

Environmentally Safe: The company’s coatings are non-toxic and environmentally friendly. Customers seek to use less toxic ingredients in their coatings, such as fluorinated compounds, in order to adhere to the trend towards sustainable products and legislations that limit the use of toxic chemicals in products.

Cost Savings: actnano’s coating takes approximately 30 seconds to apply and dry, significantly unlocking cost savings for companies involved in the electronics coating process. Compared to conventional methods, which takes approximately 2 hours of curing and masking and uses expensive equipment, actnano’s product reduces the complexity, and thus costs, involved in protecting electronics.

We believe that actnano is a category leader in the electronics coating space and pushing the limits of innovation within the industry. Our investment will support actnano as they further develop their coating solutions to expand within existing customers and into new customers with additional applications and use-cases.

Image: From left to right, Justin Kleingartner, Jim Sheridan, Taymur Ahmad, and Ivan Ardemagni.

Actnano is led by an extremely seasoned team with backgrounds in electronics, manufacturing and materials science. Taymur Ahmad’s (founder and CEO) 20 years of manufacturing management experience and Justin Kleingartner’s (CTO) extensive background in designing and developing functional coatings garner our team’s high conviction that actnano will disrupt the electronics coating industry. We are excited to partner with a world-class team as they break through the limitations of conventional methods of electronics coating!